A key element of PSI’s SBIR technology transition process is the development of vertically integrated capabilities to bring these technologies to customers. Our Wilmington, MA Operations provide those capabilities across multiple technology platforms. The 30,000 square foot facility was initially opened in 2019 to provide production capability for our growing business opportunities in high-temperature ceramic matrix composites (HT-CMC) for hypersonic systems and specialty lithium-ion battery based energy systems for unmanned vehicles. The facility has since been expanded to 55,000 square feet to accommodate further growth in those businesses as well as to provide space for our production and deployment of detection systems for Chemical, Biological, Radiological, Nuclear, and Explosives (CBRNE) defense.

The HT-CMC production facility provides the capability to do layup, de-bulking, burnout, infiltration, pyrolysis, and machining of carbon reinforced silicon carbide components for flow paths and leading edges operating at temperatures up to 4,500 degrees Fahrenheit. The entire production process is supported by extensive test and evaluation capabilities. The facility has been developed through substantial PSI capital investment to provide the large-scale autoclave, pyrolysis furnace, machine tools, and polymer impregnation systems required to create parts at or near full scale. It is supported by funding provided from organizations including the Air Force (AF) and Missile Defense Agency (MDA) for process development. In the coming months, these capabilities will be augmented through the addition of a polymer-impregnated carbon fiber tape braiding system to perform automated layup of these components, substantially reducing their cost.

The HT-CMC production facility provides the capability to do layup, de-bulking, burnout, infiltration, pyrolysis, and machining of carbon reinforced silicon carbide components for flow paths and leading edges operating at temperatures up to 4,500 degrees Fahrenheit. The entire production process is supported by extensive test and evaluation capabilities. The facility has been developed through substantial PSI capital investment to provide the large-scale autoclave, pyrolysis furnace, machine tools, and polymer impregnation systems required to create parts at or near full scale. It is supported by funding provided from organizations including the Air Force (AF) and Missile Defense Agency (MDA) for process development. In the coming months, these capabilities will be augmented through the addition of a polymer-impregnated carbon fiber tape braiding system to perform automated layup of these components, substantially reducing their cost.

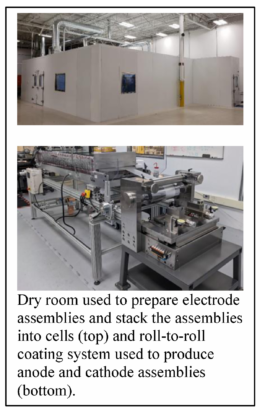

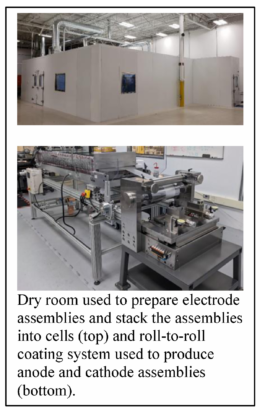

PSI’s Imperia™ Batteries production facility fills a void left in the ability to domestically produce lithium ion battery based energy systems for military applications. This comes as a result of the diversion of production capability to Asia as well as a domestic focus on the electric vehicle market. The facility brings together SBIR-developed technologies in areas such as non-flammable electrolytes, cathode and anode coatings, and specialty anode materials, as well as expertise in cell design and battery management systems to support prime contractors meeting the needs of multiple programs of record. PSI’s capital investment in the facility includes a 1,138 square foot dry room, an electrode coating line and stacker, mixing equipment, and cell testers as well as numerous building improvements to safely handle large quantities of these batteries. Program production needs will require a ten-fold increase in the current 1,000 kW-hr annual production capability using some of the recently-acquired additional space.

PSI’s Imperia™ Batteries production facility fills a void left in the ability to domestically produce lithium ion battery based energy systems for military applications. This comes as a result of the diversion of production capability to Asia as well as a domestic focus on the electric vehicle market. The facility brings together SBIR-developed technologies in areas such as non-flammable electrolytes, cathode and anode coatings, and specialty anode materials, as well as expertise in cell design and battery management systems to support prime contractors meeting the needs of multiple programs of record. PSI’s capital investment in the facility includes a 1,138 square foot dry room, an electrode coating line and stacker, mixing equipment, and cell testers as well as numerous building improvements to safely handle large quantities of these batteries. Program production needs will require a ten-fold increase in the current 1,000 kW-hr annual production capability using some of the recently-acquired additional space.

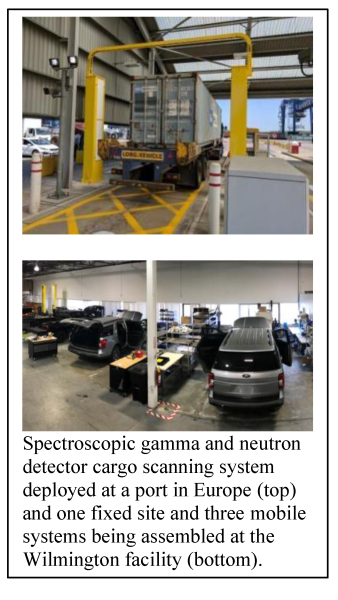

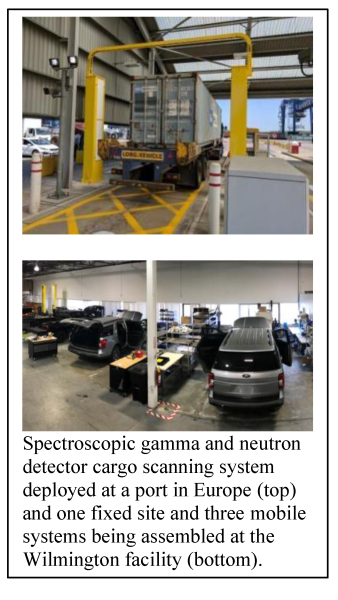

The recently-opened Detection Systems facility is focused on the production of fixed-site and mobile systems for the detection and identification of CBRNE threats and their precursors. They include networked large-scale multi-lane systems employing PSI-built spectroscopic gamma radiation detectors, new advanced technology neutron detectors, and AI-supported video technology. These systems are used by U.S. Customs and Border Protection and their international partners at border crossings in the U.S. and Europe. Mobile variants employing the same technologies, used by various law enforcement and security organizations, are manufactured and installed in PSI-modified trucks and passenger vehicles. This facility provides the ability to receive and modify these vehicles as well as build and integrate the detection systems, some of which include enhanced chemical and biological detectors.

The recently-opened Detection Systems facility is focused on the production of fixed-site and mobile systems for the detection and identification of CBRNE threats and their precursors. They include networked large-scale multi-lane systems employing PSI-built spectroscopic gamma radiation detectors, new advanced technology neutron detectors, and AI-supported video technology. These systems are used by U.S. Customs and Border Protection and their international partners at border crossings in the U.S. and Europe. Mobile variants employing the same technologies, used by various law enforcement and security organizations, are manufactured and installed in PSI-modified trucks and passenger vehicles. This facility provides the ability to receive and modify these vehicles as well as build and integrate the detection systems, some of which include enhanced chemical and biological detectors.

Special license capability enables the radiometric and spectral calibration of the nuclear detection systems. Projects supported by the Defense Advanced Research Projects Agency (DARPA) and Homeland Security enabled the improvement and integration of PSI-developed and third party commercial technologies into these systems as well as the evaluation of the deployed systems by operational users. Planning is in process to scale production to support widespread use of the technologies for personnel, vehicle, and cargo scanning at border crossings and ports of entry throughout the U.S.

This capability to develop, mature, produce, deploy, and maintain technologies in support of key national missions meets the challenge extended to small businesses by the inception of the SBIR program.

Contract News

PSI recently received the following research contracts:

“A Compact Spatially Offset Raman Sensor for Through-barrier Chemical Detection and Identification” from the U.S. Department of Homeland Security

“Measurement of the Plasma Environment in Rb Diode-pumped Alkali Lasers” from the Missile Defense Agency

“Flexible Multi-layer Emissivity Control Coatings for Spacecraft Thermal Regulation” and “Launch Hardened Cup-Cone Docking Mechanism” from the U.S. Air Force

For more PSI news, visit www.psicorp.com/news.

The HT-CMC production facility provides the capability to do layup, de-bulking, burnout, infiltration, pyrolysis, and machining of carbon reinforced silicon carbide components for flow paths and leading edges operating at temperatures up to 4,500 degrees Fahrenheit. The entire production process is supported by extensive test and evaluation capabilities. The facility has been developed through substantial PSI capital investment to provide the large-scale autoclave, pyrolysis furnace, machine tools, and polymer impregnation systems required to create parts at or near full scale. It is supported by funding provided from organizations including the Air Force (AF) and Missile Defense Agency (MDA) for process development. In the coming months, these capabilities will be augmented through the addition of a polymer-impregnated carbon fiber tape braiding system to perform automated layup of these components, substantially reducing their cost.

The HT-CMC production facility provides the capability to do layup, de-bulking, burnout, infiltration, pyrolysis, and machining of carbon reinforced silicon carbide components for flow paths and leading edges operating at temperatures up to 4,500 degrees Fahrenheit. The entire production process is supported by extensive test and evaluation capabilities. The facility has been developed through substantial PSI capital investment to provide the large-scale autoclave, pyrolysis furnace, machine tools, and polymer impregnation systems required to create parts at or near full scale. It is supported by funding provided from organizations including the Air Force (AF) and Missile Defense Agency (MDA) for process development. In the coming months, these capabilities will be augmented through the addition of a polymer-impregnated carbon fiber tape braiding system to perform automated layup of these components, substantially reducing their cost. PSI’s Imperia™ Batteries production facility fills a void left in the ability to domestically produce lithium ion battery based energy systems for military applications. This comes as a result of the diversion of production capability to Asia as well as a domestic focus on the electric vehicle market. The facility brings together SBIR-developed technologies in areas such as non-flammable electrolytes, cathode and anode coatings, and specialty anode materials, as well as expertise in cell design and battery management systems to support prime contractors meeting the needs of multiple programs of record. PSI’s capital investment in the facility includes a 1,138 square foot dry room, an electrode coating line and stacker, mixing equipment, and cell testers as well as numerous building improvements to safely handle large quantities of these batteries. Program production needs will require a ten-fold increase in the current 1,000 kW-hr annual production capability using some of the recently-acquired additional space.

PSI’s Imperia™ Batteries production facility fills a void left in the ability to domestically produce lithium ion battery based energy systems for military applications. This comes as a result of the diversion of production capability to Asia as well as a domestic focus on the electric vehicle market. The facility brings together SBIR-developed technologies in areas such as non-flammable electrolytes, cathode and anode coatings, and specialty anode materials, as well as expertise in cell design and battery management systems to support prime contractors meeting the needs of multiple programs of record. PSI’s capital investment in the facility includes a 1,138 square foot dry room, an electrode coating line and stacker, mixing equipment, and cell testers as well as numerous building improvements to safely handle large quantities of these batteries. Program production needs will require a ten-fold increase in the current 1,000 kW-hr annual production capability using some of the recently-acquired additional space. The recently-opened Detection Systems facility is focused on the production of fixed-site and mobile systems for the detection and identification of CBRNE threats and their precursors. They include networked large-scale multi-lane systems employing PSI-built spectroscopic gamma radiation detectors, new advanced technology neutron detectors, and AI-supported video technology. These systems are used by U.S. Customs and Border Protection and their international partners at border crossings in the U.S. and Europe. Mobile variants employing the same technologies, used by various law enforcement and security organizations, are manufactured and installed in PSI-modified trucks and passenger vehicles. This facility provides the ability to receive and modify these vehicles as well as build and integrate the detection systems, some of which include enhanced chemical and biological detectors.

The recently-opened Detection Systems facility is focused on the production of fixed-site and mobile systems for the detection and identification of CBRNE threats and their precursors. They include networked large-scale multi-lane systems employing PSI-built spectroscopic gamma radiation detectors, new advanced technology neutron detectors, and AI-supported video technology. These systems are used by U.S. Customs and Border Protection and their international partners at border crossings in the U.S. and Europe. Mobile variants employing the same technologies, used by various law enforcement and security organizations, are manufactured and installed in PSI-modified trucks and passenger vehicles. This facility provides the ability to receive and modify these vehicles as well as build and integrate the detection systems, some of which include enhanced chemical and biological detectors.