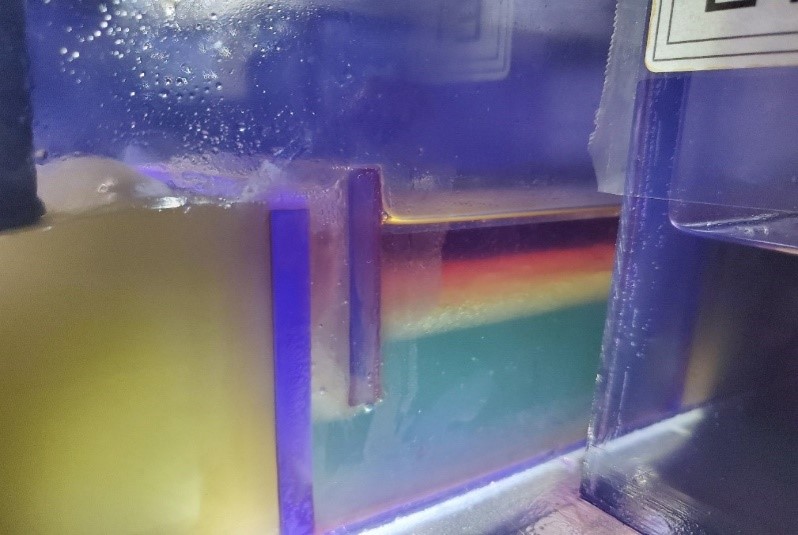

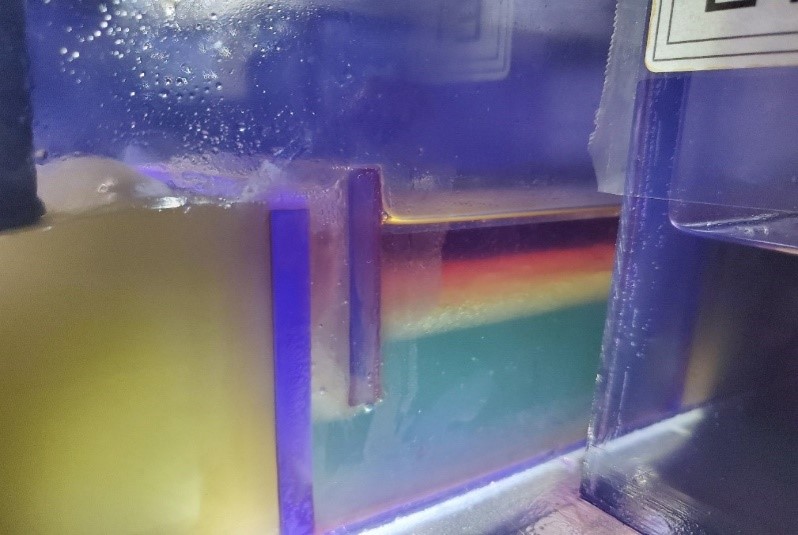

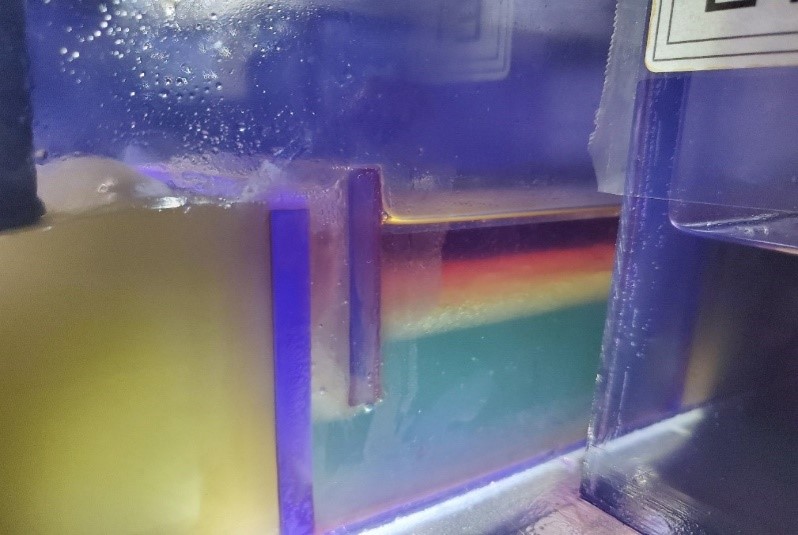

This one-of-a-kind plant was a first for PSI, in that we took a chemical process performed in beakers and test tubes, and brought it all the way to the pilot scale. The next steps are to work with our government, academic, utility, and commercial partners to scale-up the operation further, process many tons of coal ash, and produce as much rare earth material as possible.