Energetics

Energetics

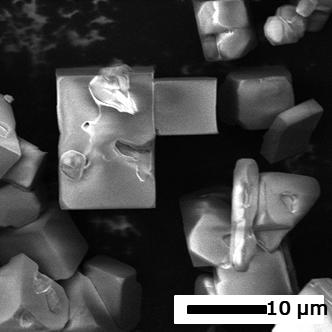

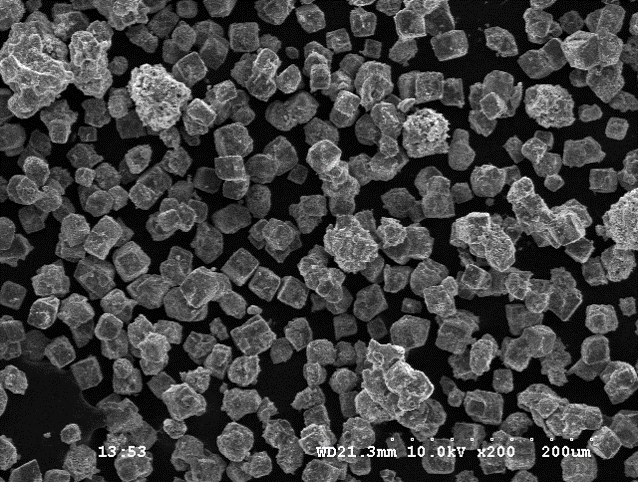

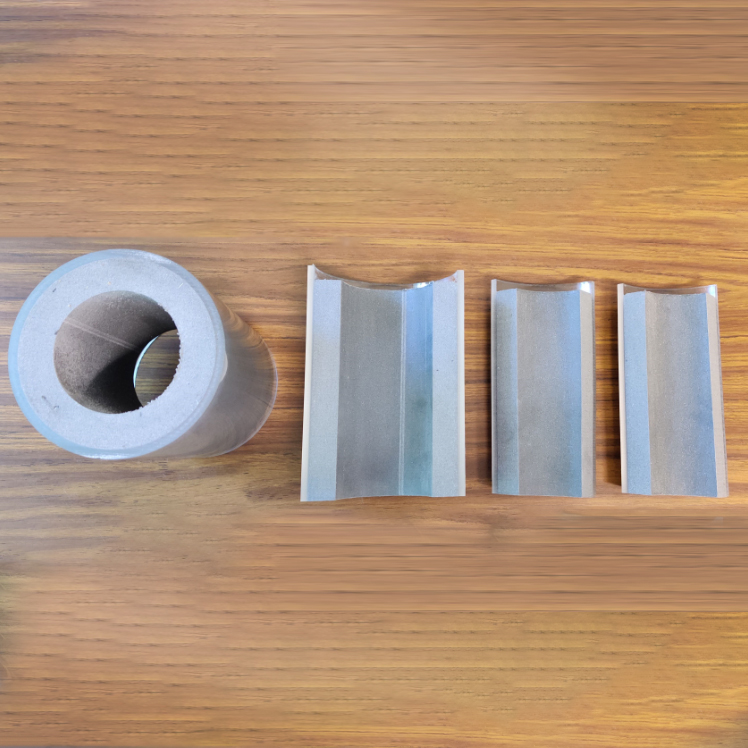

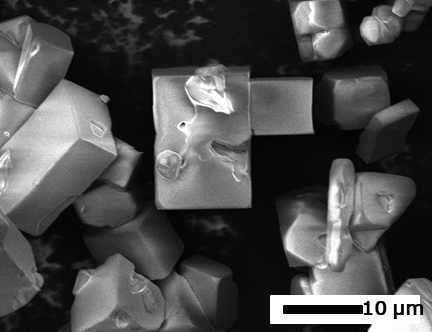

PSI has expertise in gas, liquid and solid material characterization. Materials are characterized by optical microscopes and a Field Emission scanning electron microscope (SEM). The SEM includes energy dispersive X-Ray Analysis (EDX) for rapid, high resolution imaging with identification of elements present on the sample. PSI also employs light interrogation techniques such as FTIR and UV-VIS for characterizing the samples. Other samples are analyzed using standard laboratory techniques, including particle size analysis, GC-MS, GC-TCD, pycnometry, and NMR. Mechanical properties of energetic materials are determined using Frank Bacon tension and compression testing machine. Thermal behavior is quantified using bomb calorimetry, Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC).