Capability Description: A core focus within solid rocket motor research is the development and demonstration of critical system components to enhance mission performance, safety and sustainability of tactical systems. We have continued to lead in developing innovative solutions to complex system problems with multi-dimensional constraints that have shown to augment missile performance and their insensitive munition (IM) compliancy. Our core technologies include motor cases, health monitoring sensors, energetic ingredient refinements, plume signature diagnostics, formulation development, igniters, and measurements for validation of modeling and simulation tools.

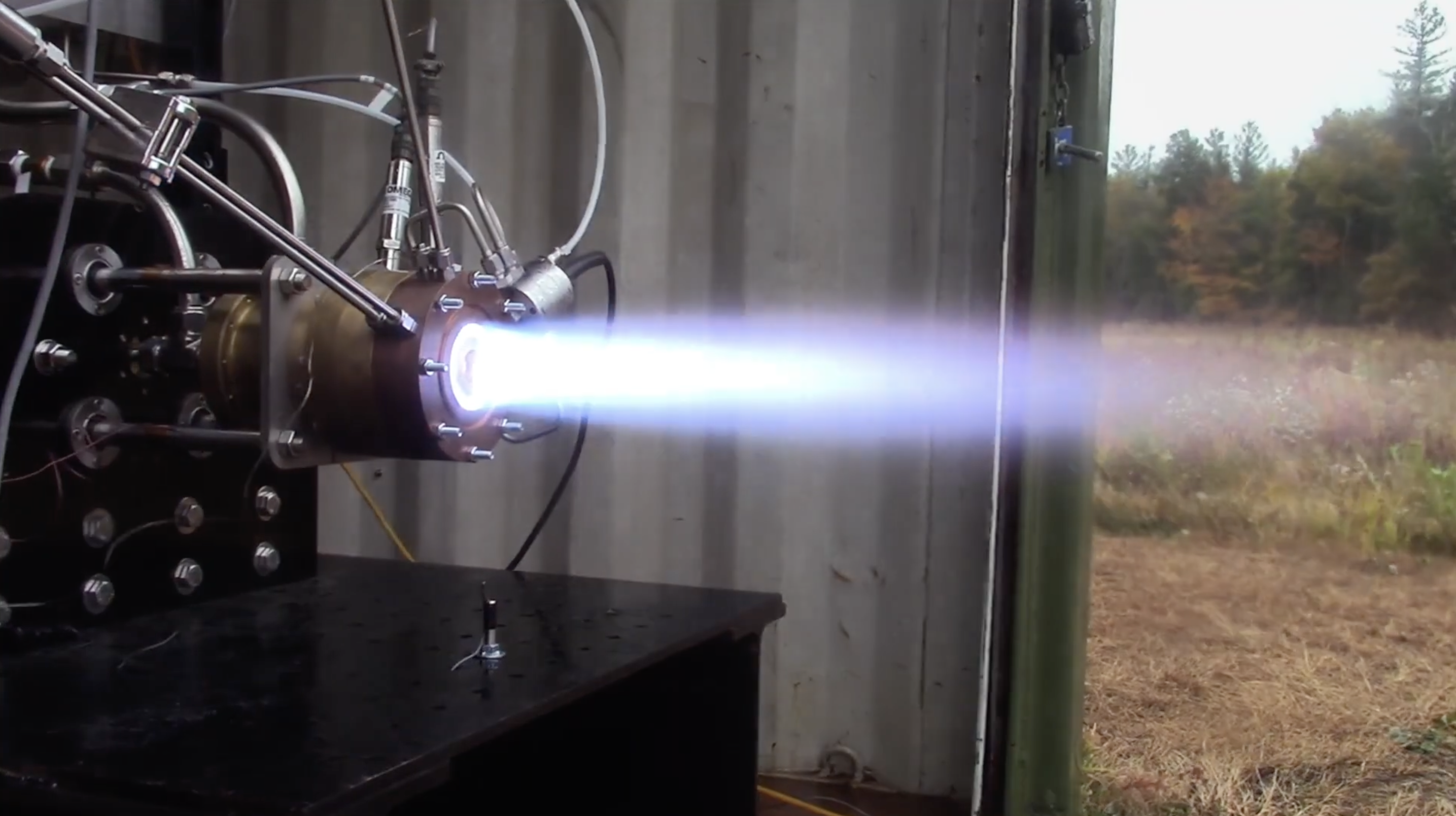

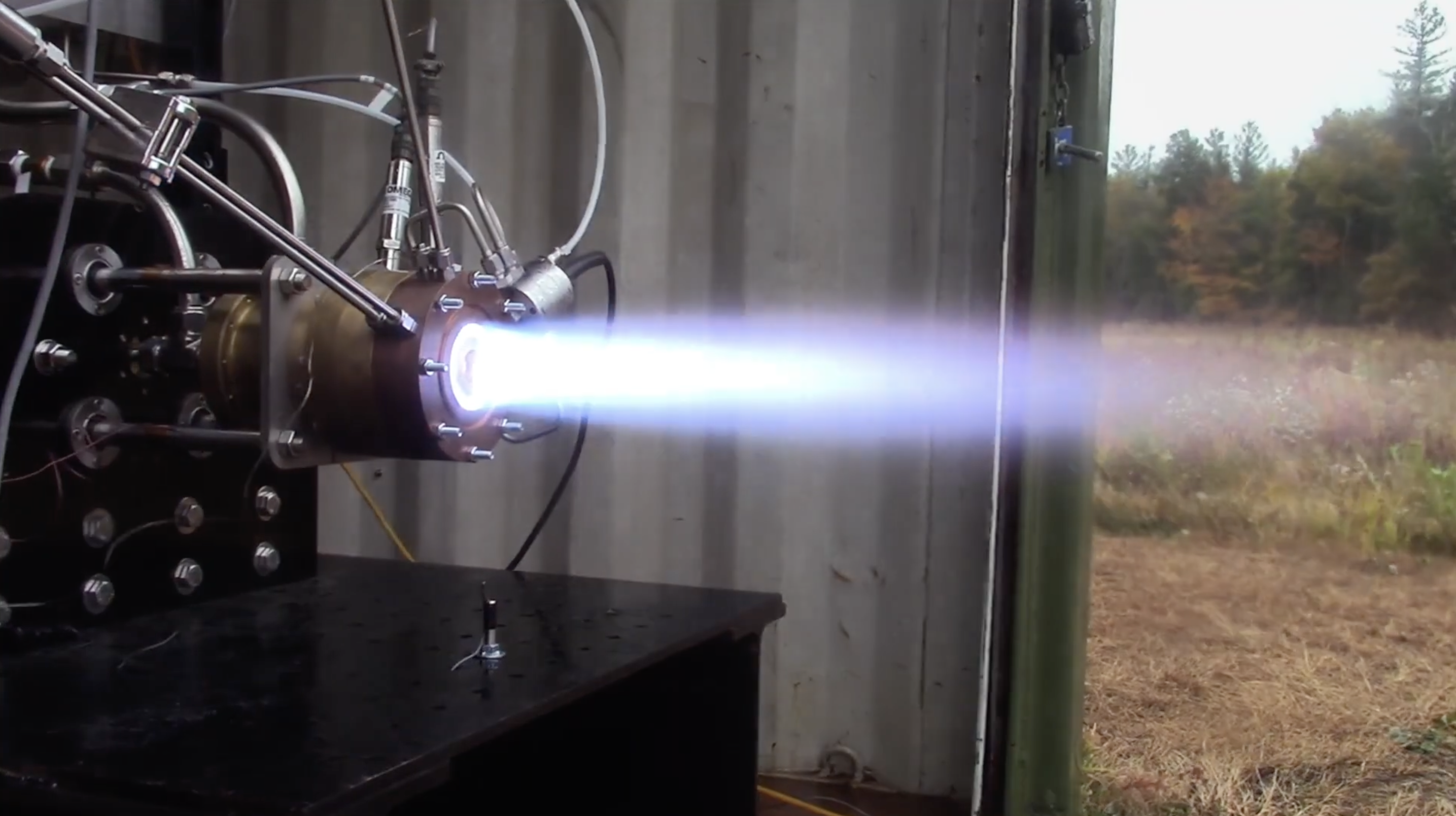

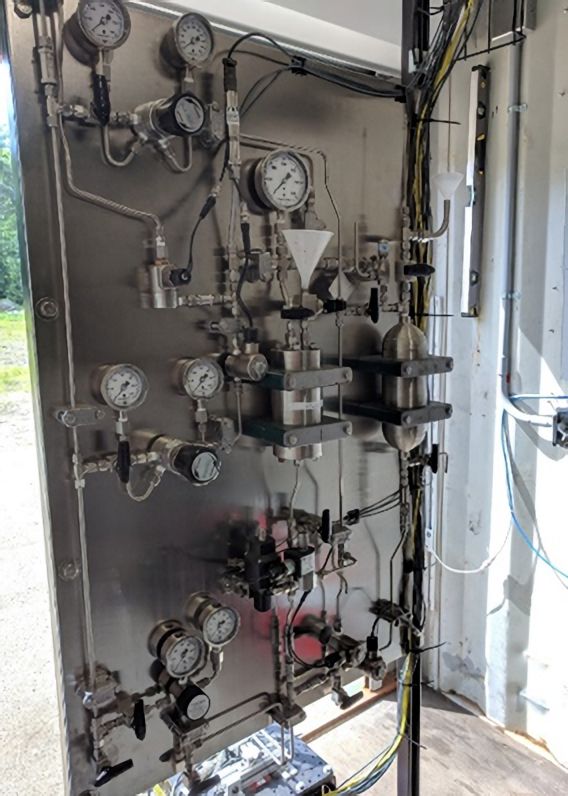

Key Features: PSI evaluates solid rocket motors using four different test cells at our New Hampshire location, including:

- 2×4 Solid Rocket Motor Test Cell

- 5”-8” Solid Rocket Motor Test Cell

- Divert and Attitude Control Systems (DACS) Test Stand

- Experimental 2-D Solid Rocket Motor – 500 lbf Thrust