Lyophilization Process Development

Key Features

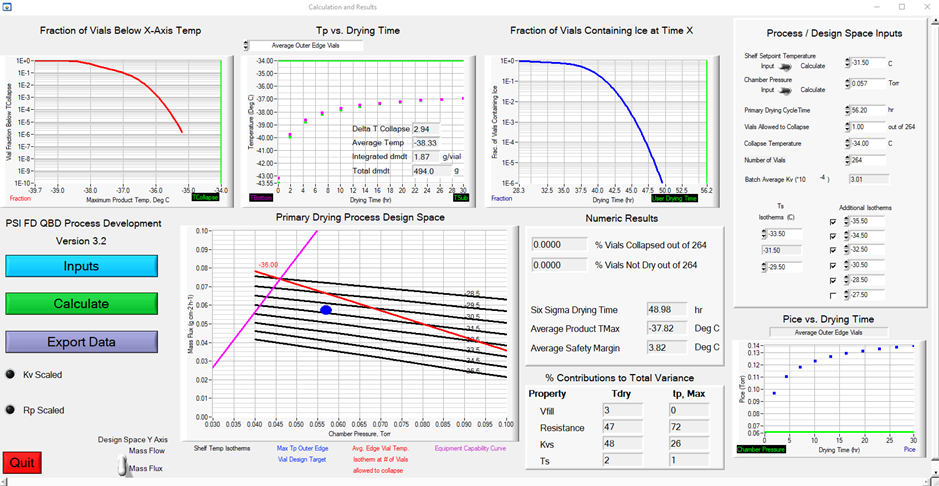

Process Models and Automated Process Development using a heat and mass transfer model of heterogeneous freeze drying. TDLAS-based SMART Freeze Dryer, PAT-Enabled Freeze Dryer.

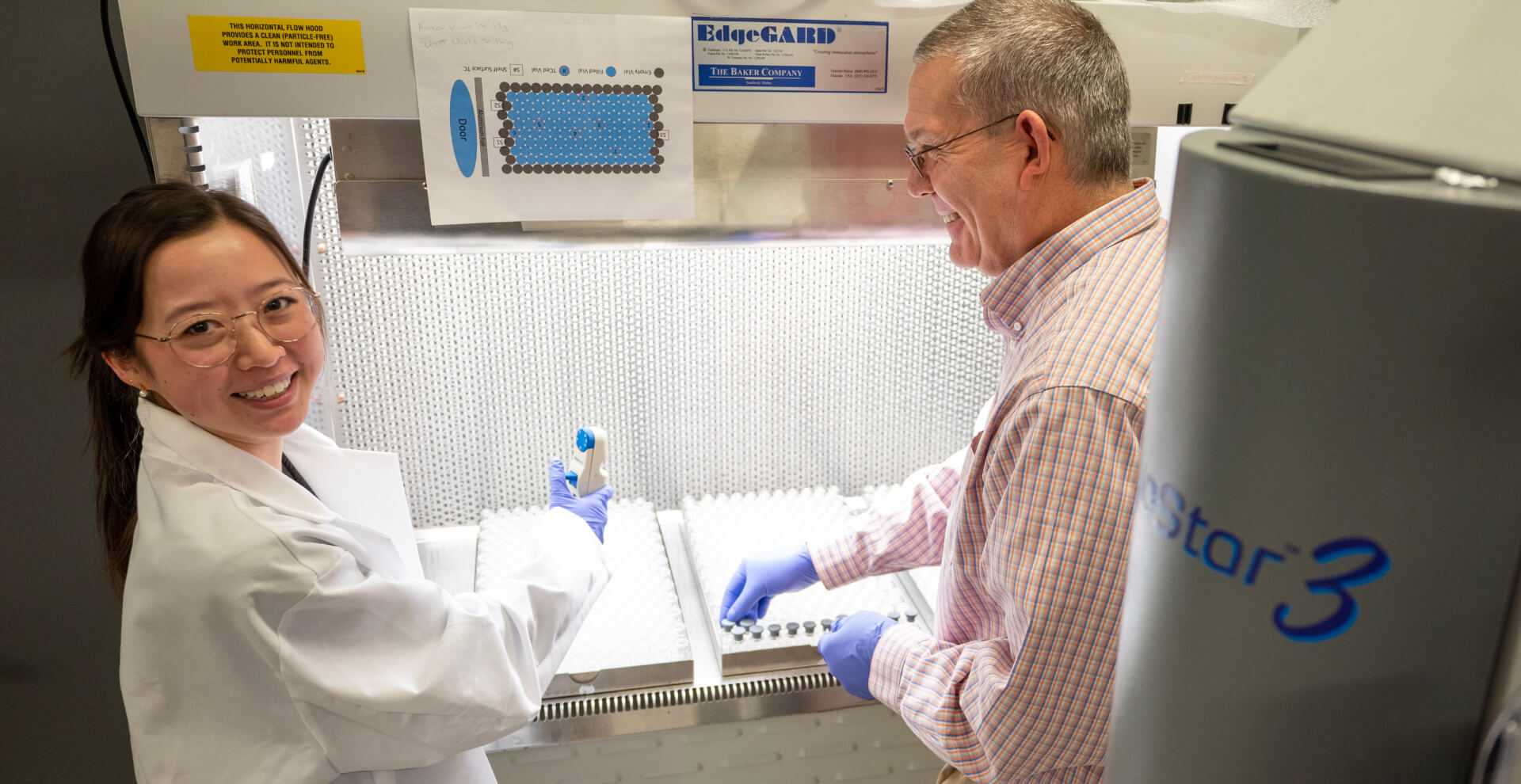

Physical Sciences Inc., in collaboration with UConn, has developed heat and mass transfer models and process control algorithms that account for intra- and inter-batch drying heterogeneity. These tools have been integrated within SP Industries Lyostar 3 / 4 lab scale and LyoConstellation pilot scale freeze dryers. PSI has the staff, tools and collaborations needed to develop process cycles for your product.

- Demonstrated, accurate modeling capability

- PAT-Enabled Lyostar 3 and Lyostar 4 freeze dryers

- Access to a PAT-Enabled LyoConstellation S20 freeze dryer located at UMass Lowell.

Development of efficient freeze-drying cycles based on QbD principles, accounting for both intra- and inter-batch drying heterogeneity, assuring that all vials within the drying chamber achieve high quality.