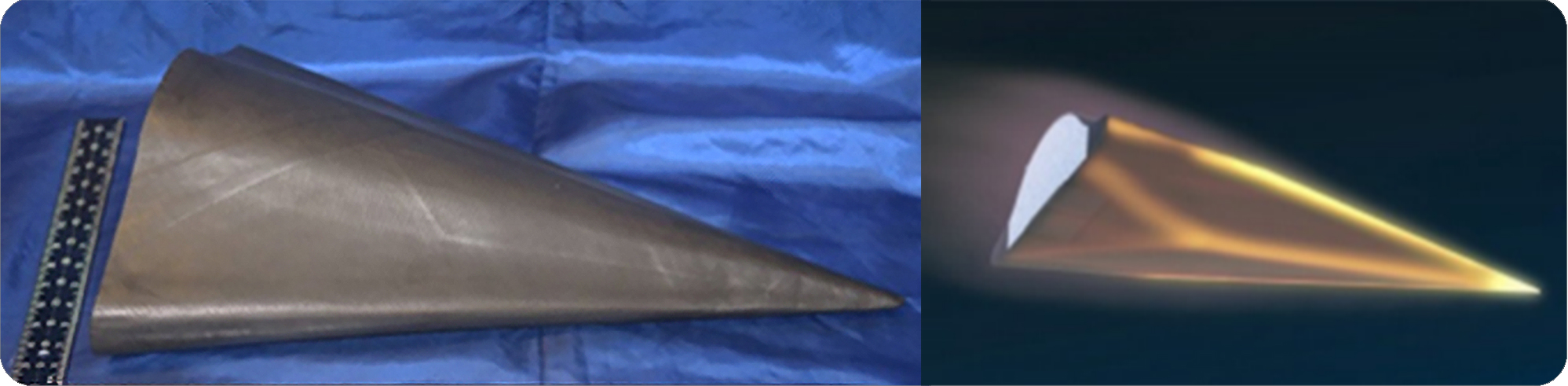

Aero-shell Glide bodies fabricated from PSI’s PSC-10 ceramic composites

Key Features:

- Carbon fiber-reinforced SiC Matrix Composite

- Service temperatures up to 3000°F

- Tensile Strengths of 35 KSI (for quasi-isotropic ± 45° Layups)

- Compatible with UHT-21 as a Hybrid System, as well as production via Pre-preg Braiding, Z-pinning, and as a Flexible TPS.

- Production of PSC-10 components in PSI’s Wilmington facilities can have fabrication timelines as short as 8 weeks from start to finish.