Wilmington, MA

PSI’s Wilmington, MA facility is the next step in our expansion into the production of specialty materials and components by providing 30,400 square feet of dedicated and specialized manufacturing space.

It is home to our Advanced Composites integrated high temperature ceramic matrix composites operations and provides:

Furnace with RA 330 retort

-

Expanded chemical vapor deposition capability for providing barrier coatings for composite reinforcing fabrics.

-

Environmentally controlled spaces for the production, storage, and layup of components produced from our proprietary ceramic matrix formulations.

-

Preform burnout as well as polymer impregnation and pyrolysis (PIP) capability through a newly-acquired high-temperature furnace with a 72 x 60 x 36 inch working zone retort operating at temperatures up to 1200C.

-

Mandrel and component machining capability using high capacity CNC lathe and milling machines as well as a laser

The facility is also home to our Energy Technologies operations and its Imperia Battery product line. The facility provides:

- A 1,150 square foot dry room equipped with an automated cell stacker, calendering station, cell filling and sealing stations, custom electrode production system, electrode punching stations, pouch cell former, powder and slurry mixing equipment, and an ultrasonic welder.

* Test capability including cyclers and test cabinets to allow simultaneous testing of 100+cells. Testers include multiple Arbin battery cyclers with Gamry AC impedance capability and a Solartron AC Impedance analyzer.

The battery facility is supported by 13 staff members currently providing a production capability of 40 cells per week with a target of 100+ cells per week in six months. In addition to battery production, this staff supports advanced battery development through contracts funded by organizations such as the U.S. Advanced Battery Consortium and the Massachusetts START Program.

Epping, NH

PSI’s Epping, NH location hosts specialized test facilities for the Propulsion and Energetics (P&E) Group, a multi-disciplinary team of scientists and engineers (chemical, aerospace, and mechanical), who conduct R&D for innovative propulsion and energetics technologies. The outdoor range includes seven enclosed propulsion test cells, two propellant mixing labs, and a control room/office. Activities conducted at Epping include:

Experimental Solid Rocket Motor for Plume Characterization

-

Solid Propellants: novel formulations and ingredients for increased burn rate, increased specific impulse, improved storability, faster ignition, insensitive munition compliance, and lower cost.

-

Liquid Propellants: novel formulations and ingredients for less toxicity, improved storability, lower vapor pressure, faster ignition, and increased specific impulse.

-

Rocket Propulsion Systems: igniters, propellant health monitoring systems, plumbing components, and engine nozzles.

RSI’s Space Weather Program

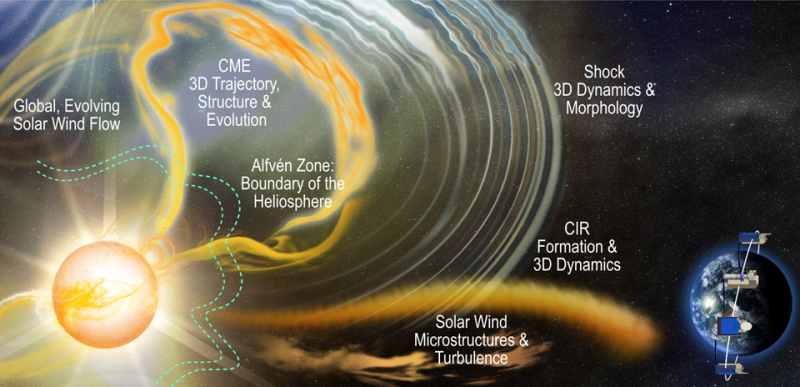

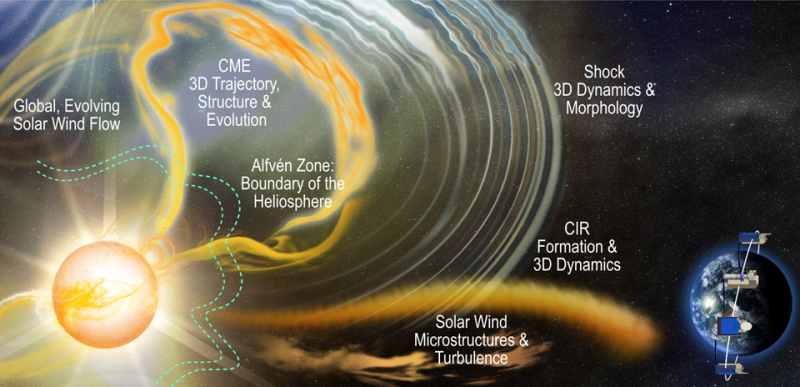

Research Support Instruments (RSI), a wholly owned subsidiary of PSI, has begun work on a space weather program that augments their recent work on the currently orbiting Wide-field Imager for Solar PRobe Plus (WISPR); the program has since been renamed Parker Solar Probe (PSP). Whereas PSP focuses on in situ coronal measurements, the Polarimeter to Unify the Corona and Heliosphere (PUNCH) mission will focus directly on the Sun’s outer atmosphere, the corona, and how it interacts with the inner heliosphere.

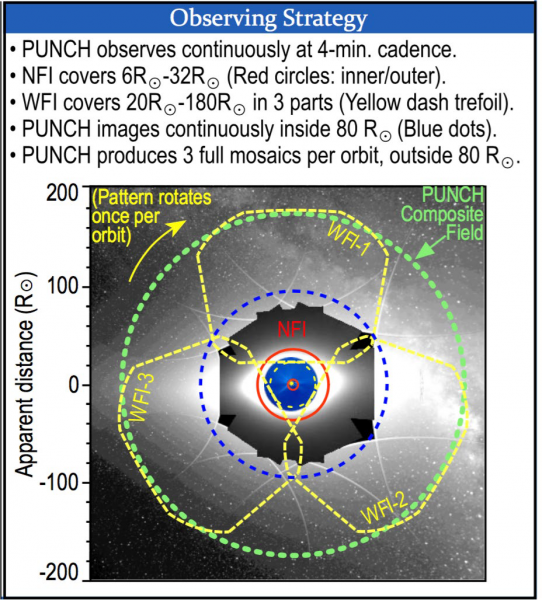

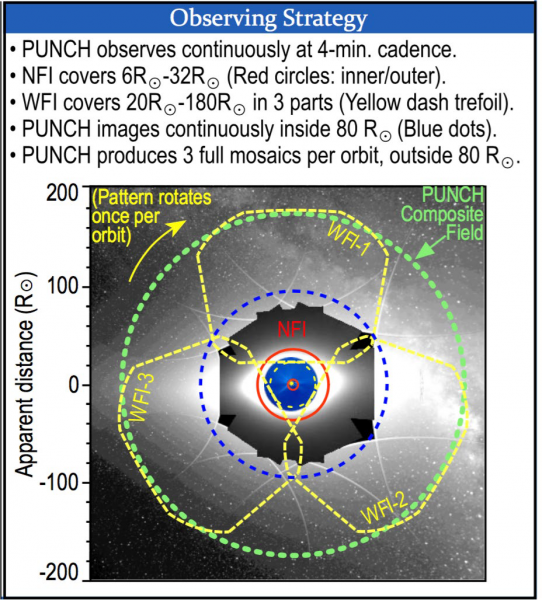

Illustration of how the four imagers work in concert to obtain a single composite image of the corona and inner heliosphere

PUNCH will make 3-dimensional (stereoscopic) observations of the young solar wind from the solar corona to the inner heliosphere, closing a 50-year gap in measurement and understanding. A constellation of 4 small satellites in Sun-synchronous LEO produces deep field, continuous, 3D images of the corona and young solar wind from 6 to 180 R (solar radii) in polarized visible light. Each spacecraft carries one instrument. A Narrow Field Imager (NFI) captures the entire outer corona from 6 to 32 R. Three Wide Field Imagers (WFIs) capture from 20 to 180 R.

A common imager detector allows images from all four Observatories to be combined into higher order science data products. The images allow detection of a mass ejected by the Solar Corona and tracking of the evolution of the structure of the mass as it enters the Heliosphere and evolves over time.

Depiction the scientific goals of the mission and where they are measured

The program is a joint effort between Southwest Research Institute (SwRI), the Naval Research Laboratory (NRL), and RAL Space. The NRL team will be building the Near-field imager (NFI) and the polarizing filter wheels (PFW) that will be used on each instrument.

For more information, contact Mark Boies, RSI Systems Engineer.

Contract News

PSI recently received the following research contracts:

Passive Cathode Coatings and Devices for Spacecraft Charge Mitigation and Towed Optical Plume Simulator Emitter Enhancements from the U.S. Air Force

Nontoxic, Environmentally Friendly, Cellulose-based Carbon Material for Supercapacitor Applications from the Missile Defense Agency (MDA)

Emergency Pneumatic Wire Rope and Cable Cutter and Multi-Band Laser Source for Atom Interferometry to PSI’s Subsidiary Q-Peak, Inc. from the U.S. Navy, Naval Air Warfare Center

Optical Probe for in situ Assessment of Pulmonary Fibrosis from the National Institutes of Health

Physical Sciences Inc. | contact@psicorp.com | (978) 689-0003 |

© 2020 Physical Sciences Inc.

Subscribe to the PSI Newsletter