Newsletter

In this issue of the PSI newsletter, we highlight two technology updates: PSI’s TDLAS-based SMART Freeze Dryer Technology and PSI’s Lidar Development for the Navy.

TDLAS-based SMART Freeze Dryer Technology

Physical Sciences Inc., (PSI) in collaboration with the University of Connecticut and SP Scientific, recently completed an NIH-supported Small Business Innovation Research (SBIR) program for the development and testing of a Tunable Diode Laser Absorption Spectroscopy (TDLAS) based SMART Freeze Dryer technology. This technology enables both freeze drying experts and scientists/engineers with limited freeze drying experience to develop a pharmaceutical product lyophilization cycle within a single experiment. This new product enables: 1) application to all product formulations, including high weight percent amorphous products (including emerging biotechnology products); 2) elimination of the need for the freeze dryer to be equipped with a fast closing isolation valve; and 3) applicability to all size freeze dryers, providing common data sets and use of common procedures as the process is scaled-up.

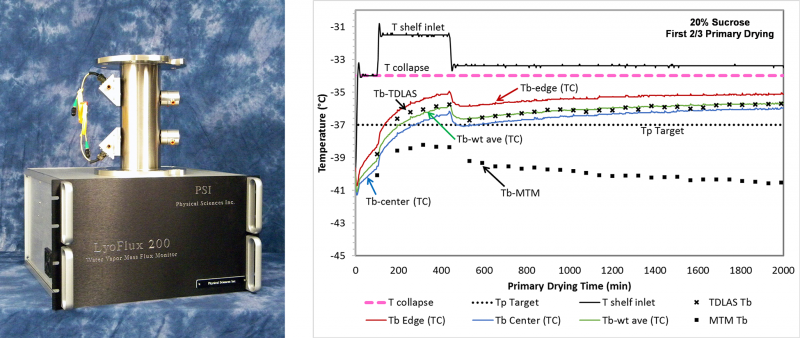

LyoFlux® TDLAS sensor and example freeze drying cycle development

The development of biologic pharmaceutical products, the fastest growing segment within the pharmaceutical industry, often requires formulations that must be freeze dried to stabilize products so they can be stored, shipped and reconstituted for use. The development of economically viable drying processes that produce high quality product is critical for the success of these drug products and is one element of drug cost control. This technology directly addresses this aspect of pharmaceutical manufacturing and has resulted in a product that will be used by process development scientists and production staff at pharmaceutical companies, supporting the US FDA and industry Process Analytical Technology (PAT) and Quality by Design (QbD) initiatives.

The combination hardware/SMART algorithm software product leverages an existing process control algorithm based on a heat and mass transfer model of freeze drying and enables pharmaceutical scientists to rapidly develop robust product freeze drying cycles during one experiment. Sensor enabled water vapor mass flow rate determinations, combined with the model, provide accurate, non-intrusive, determination of the product temperature during drying (error <1 degree C). Product temperature determinations provide a process control parameter for developing and controlling the freeze drying process during laboratory and pilot scale experiments. Extensive laboratory experiments were carried out at PSI, the University of Connecticut and SP Scientific to assess measurement accuracy and automated process cycle control for the development of optimized drying operations. The TDLAS SMART Freeze Drying product is currently in beta site testing and will be offered for sale through SP Scientific in Spring 2019.

PSI’s Lidar Development for the Navy

This past summer, PSI participated in a Navy field exercise held at Naval Base Ventura County (NBVC), CA. PSI deployed its Shipboard Atmospheric Extinction Lidar (SAEL) to the Navy Sea Range at the Naval Air Station (NAS), Pt. Mugu (part of NBVC) as part of CABLE-TRAX West in August 2018. This was the second in a series of exercises held both to inter-compare new instrumentation developed to provide environmental situational awareness in support of high energy laser (HEL) weapon operation and to gather data to support development of the latest Navy computational models of turbulence and extinction.

PSI’s SAEL on the beach at the Sea Range, NAS Pt. Mugu, August 2018

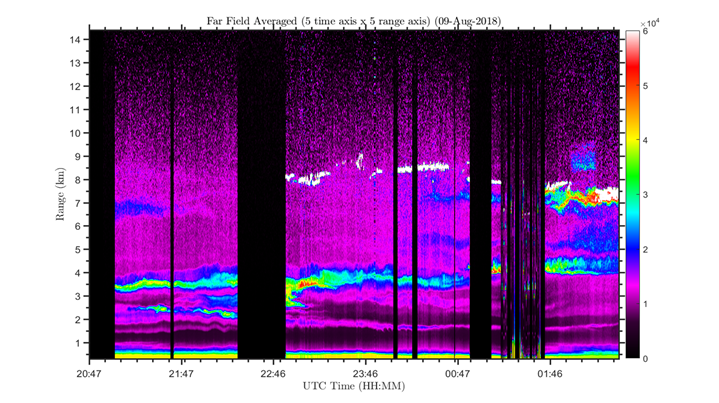

Beam propagation at ranges of several kilometers can be degraded by atmospheric turbulence and extinction (both absorption and scattering). The Navy is supporting the development of several different instruments that can individually measure some or all of these effects, some with range resolution. PSI has been supported by a NAVSEA SBIR program since 2013 to develop a very compact lidar for characterizing atmospheric extinction at the wavelength of the weapon. PSI’s SAEL compared very favorably with the Navy’s Integrated Atmospheric Characterization System (IACS) built by Georgia Tech Research Institute (GTRI) and now operated by NAS Pt. Mugu. IACS is a large frame constellation of three lidars on one gimbal mount. The system measures extinction, turbulence and water vapor. Despite being restricted by Sea Range control to a limited range of azimuth and elevation angles, SAEL demonstrated volumetric scanning for the first time. When deployed on a ship, SAEL is intended to provide umbrella coverage to the ship by scanning a hemisphere centered on the ship and updating every 15 – 30 minutes 24/7.

PSI SAEL Data: 09-August 2018, 45º Elevation. Range-Corrected Backscatter Lidar Signal, kcps-km2

IACS, and instruments like it, will soon provide Range test support as new High Energy Laser (HEL) systems like Laser Weapon System Demonstrator (LWSD) and High Energy Laser Integrated with Optical Dazzler and Surveilance (HELIOS) mature to field qualifications before deployment. Based on SAELs successful intercomparison to IACS, PSI recently received a RFQ from NAS Pt. Mugu to deliver a system that will be deployed at the Sea Range.

Contract News

PSI recently received the following research contracts:

“Optical System for Monitoring Net Ocular Blood Flow” and “Energy Scavenging Technology for Electrical Power Generation in High Energy Intensity Environments” from the National Aeronautics and Space Administration (NASA).

“LabHand Payload for InstantEye sUAS Platform for Continuous Indoor Transport of Laboratory Consumables” from the National Institutes of Health.

“New InstantEye Mk-3 GEN5-D1 SUAS System Procurement” from United States Marine Corps.

For more PSI contract news, visit www.psicorp.com/news.

Physical Sciences Inc. | contact@psicorp.com | (978) 689-0003 |

© 2018 Physical Sciences Inc.