Newsletter

InstantEye® Robotics Releases Enhanced Mk-3 sUAS Systems

PSI’s InstantEye Robotics Division recently introduced two new versions of its Mk-3 all-digital soldier sUAS systems. These systems are designed and manufactured in our ISO 9001-certified US facility located in Andover, MA, using compliant US-sourced components.

InstantEye Mk-3 GEN5-D1 (E) with gimbaled/EIS EO/IR camera

The Mk-3 GEN4-D1/D2 HL (Heavy Lift) system has been enhanced to provide precise payload delivery using optically stabilized flight in GPS degraded/denied environments. The Enhanced Payload Delivery Mechanism was developed to support the Army’s Render Safe – Sets, Kits, and Outfits (RS-SKO) program. It provides the ability to aerially deliver explosive charges for Explosive Ordinance Defeat (EOD), day or night. Payloads up to 3 lbs. are delivered with 4-inch positioning accuracy at ranges exceeding 200 meters, providing mission capability at speed and over terrain inaccessible by ground robotic systems.

Image from 640 x 512 thermal imaging system demonstrating ability to recognize a person with a weapon at 40 meters.

The superior endurance of all our enhanced systems is provided using specially-designed, high-capacity/high-rate mission batteries produced by our Imperia Batteries Division. The Imperia team works closely with our sUAS engineering and manufacturing staff to match battery performance to aircraft flight demands while meeting international safety requirements for Li-ion batteries.

For more information about InstantEye Robotics enhanced Mk-3 sUAS systems, please contact Michael Mackiewicz, Director of Operations: mmackiewicz@psicorp.com

Smart Moisture Absorbing Foams (SMAFs)

Physical Sciences Inc. (PSI) in collaboration with Cascade Designs Inc (CDI) and the University of Massachusetts Amherst (UMass) has been awarded a program from the Defense Advanced Research Projects Agency (DARPA) to develop a new atmospheric water extraction (AWE) device that can recover clean drinking water from air. The developed technology is intended to supply water in remote areas, to forward to deployed soldiers, and during emergency situations.

Water is a critical resource for survival. Many remote locations have limited or polluted water supplies. Existing methods of water purification, such as desalination, require large pieces of equipment and are energy intensive. Further, water is cumbersome to transport, presenting a logistical and economic challenge for supplying water to distant areas. The PSI team aims to overcome these challenges by creating a new class of water capturing materials incorporated into an ultra-lightweight and portable water harvesting system.

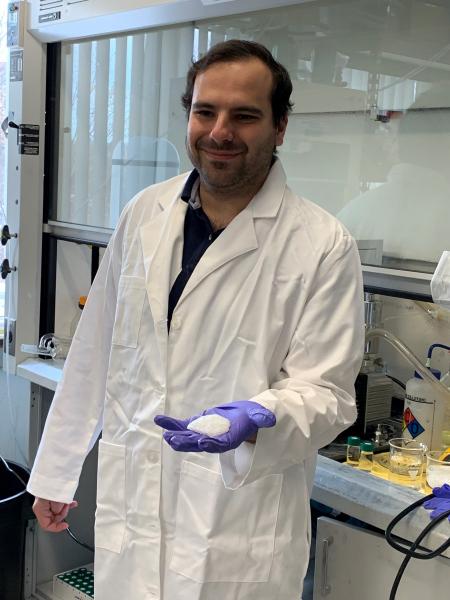

Dr. David Gamliel, Principal Scientist/ Engineer, holds a Smart Moisture Absorbing Foam (SMAF)

The centerpiece of the team’s technology is a novel Smart Moisture Absorbing Foam, or a SMAF. The SMAF will capture atmospheric water across a wide variety of environments, and over a range of temperatures and relative humidity. The SMAF also has very high water storage capacity, enabling daily operational cycles and minimizing frequency of user interaction. The key property of the SMAF is that water is released by compression. The material is ‘smart’ because it switches from hydrophilic (‘water loving’) to hydrophobic (‘water rejecting’) as it is compressed – thereby expelling any trapped water.

Typical state of the art water capture materials release water by energy-intensive heating. Releasing water by compression greatly reduces the amount of energy required to power the system, enabling ultimate portability.

As a part of the effort, the SMAF material will be incorporated into several prototype devices. The final device will be easily carried by an individual as a primary water supply. The team aims to create a lightweight, compact, durable and easy to operate water harvesting system that fits within the stringent DARPA size, weight and power targets.

The goal of this new research is a portable and robust system capable of extracting potable drinking water from ambient air. To ensure portability, the system is designed to fit within a strict size, weight and power envelope. Such technology has game-changing implications for both military and humanitarian purposes.

For more information about PSI’s atmospheric water extraction technology, please contact Dr. Peter Warren, Vice President of PSI’s Materials Systems Division: .

Read the DARPA article: Teams Selected to Develop Technology to Capture Potable Water from Air Under DARPA’s AWE Program

Contract News

PSI recently received the following research contracts:

“Versatile Eye Tracking for Improved High-resolution Retinal Imaging” from the National Institutes of Health;

“Multilayer Flexible Thermal Protection System (TPS)” from the Missile Defense Agency (MDA);

“Additively Manufactured Scramjet” from the U.S. Air Force;

“A Microwave Measurement Facility for Dispersed RF Chaff Materials”, AI-Assisted Clutter Mitigation for Standoff LIDAR Plume Detection” and “High Energy, Large Projectile Recovery (HELPR)” from the U.S. Army.

For more PSI news, visit www.psicorp.com/news

Physical Sciences Inc. | contact@psicorp.com | (978) 689-0003 |

© 2021 Physical Sciences Inc.